Battery Technology

The battery was invented long before the automobile and its primary task is to store direct current (DC) so it can be used when needed. In modern passenger cars and light commercial vehicles, 12-volt DC is typically used. For heavier vehicles such as trucks and buses, 24 volts is more common. However, this is not true in every country — for example, many trucks in the United States still use 12-volt systems.

To interpret a battery’s characteristics and, for example, calculate how long a charge will last, you need to be familiar with four concepts:

• Voltage (Volts)

• Power (Watts)

• Current (Amperes)

• Ampere-hours (Ah)

VOLTAGE (VOLTS)

Direct current (DC) has a clear Achilles’ heel: resistance. To ensure that the proper voltage (Volts) reaches the load — for example, a lamp or an electric motor — it’s critical to use the correct cable gauge. A cable that is too thin or too long leads to what’s called voltage drop, which means electrical energy is lost along the way from the power source to the load, causing reduced performance — for instance, dimmer lights and slower-running electric motors.

A major problem with voltage drop is that the lost electrical energy is converted into heat, and a cable’s resistance increases with temperature. For every one-degree increase, resistance rises by approximately 0.4%. That creates a negative spiral: more resistance generates more heat, which in turn causes even higher resistance. This can lead to a cable fire that, in the worst case, may ignite the entire vehicle. If the cable length is doubled, the resistance also doubles. If, instead, the cross-sectional area of the cable is halved without increasing its length — for example by using a thinner cable — the resistance likewise doubles.

By doubling the system voltage — for example from 12 to 24 volts — you effectively halve the current for the same power, which reduces losses and heat and lets you step down the cable gauge without increased heat buildup. As mentioned earlier, resistance increases with cable length, which is why heavier vehicles like trucks and buses commonly use 24-volt systems to save on cable material (copper). For the same reason, higher voltages may also become more common in regular cars in the future. One example is the Tesla Cybertruck, which already uses a 48-volt system. Many electrical components — such as warning lights, auxiliary driving lights, and work lights — are therefore designed to operate over a wide voltage range, often between 10 and 30 volts.

POWER (WATTS)

Power indicates how much energy an electrical load requires to operate correctly. If, for example, a lamp is rated at 30 watts, it means it needs 30 watts of power to provide the proper brightness and function correctly.

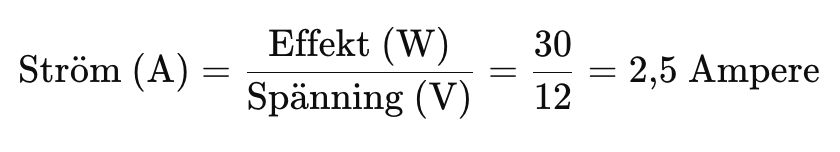

Current (amperes)

If we have a lamp with a power of 30 watts and a voltage of 12 volts, we can calculate how much current it draws by using the formula:

This type of calculation is useful for many purposes — for example, you can determine which fuse you should use and estimate how long the battery can power this lamp.

AMPERE-HOURS (Ah)

Batteries come in different sizes and capacities. The batteries we stock at Work System are labeled 100 Ah (ampere-hours). The label indicates, theoretically, that the battery can deliver:

• 1 ampere for 100 hours

• 2 amperes for 50 hours

• 10 amperes for 10 hours

...and so on. Note that this is a theoretical estimate; in practice, a battery’s performance is affected by many different factors.

EXAMPLE 1

We’ll use the earlier example of a lamp rated at 30 watts and powered by 12 volts. First, we calculate the current draw:

Next, we can calculate how long a 100 Ah (ampere-hours) battery can power the lamp:

EXAMPLE 2

A customer wants to install electric heating in the cargo area of their vehicle. The idea is to use a space or cabin heater rated at 1,400 watts / 230 volts to keep tools and rain gear warm and dry during the winter season.

To power this heater, we need:

• An auxiliary battery as the energy source

• An inverter that converts 12-volt DC to 230-volt AC

• An inverter with an output of at least 1,500 watts to ensure it can run the heater.

Now the customer wants to know how long the heater can run using the auxiliary battery. To answer that, we start by calculating how much current is required from a 12-volt battery to power a 1,400-watt heater:

But since an inverter is not 100% efficient, there is typically about a 10% conversion loss. Therefore, we multiply by 1.1:

Now that we know how much the heater requires, we can easily calculate how long our 100 Ah auxiliary battery can theoretically power it:

Let’s convert that to minutes:

If an EFB (Enhanced Flooded Battery) is installed, it can only deliver about 50% of its 100 Ah without risking reduced service life. That immediately halves the runtime from 46.8 to 23.4 minutes.

Conclusion: This calculation clearly shows that electric heating in the cargo area is highly energy-intensive and not a sustainable solution for the customer. Installing more batteries to extend runtime is not practical because the vehicle’s charging system usually cannot efficiently recharge multiple batteries while driving. The recommended solution is instead to install an external 20A charger that can be connected to the grid and charge the auxiliary battery overnight.

Battery Types

At present, an AGM battery is the best option in Work System’s range. While it is a bit more expensive than a traditional lead-acid battery, this is offset by several advantages:

• Longer service life

• Better tolerance to deep discharge

• Higher usable capacity (more Ah can be utilized)

If price is the deciding factor, an EFB battery can be a more affordable alternative. However, it’s important to understand the limitations of EFB compared to AGM to make an informed choice. Once the value of AGM is understood, price typically becomes less decisive. A lithium battery can be an option, but for now it is significantly more expensive. It also has certain limitations in cold environments, as low temperatures can impair both charging and current delivery — which is particularly problematic if the battery is used to power an inverter.

LEAD-ACID (WET)

The most traditional and still the most common vehicle battery type is AMF (AutoMotive Flooded) — a classic flooded lead-acid battery. It consists of six cells with upright lead plates submerged in liquid electrolyte (battery acid). When fully charged, it delivers approximately 12.8–12.9 volts at rest (no load).

If the voltage drops below 12.4 volts, the lead plates inside the battery begin to sulfate (degrade), which means they deteriorate and lose capacity. This occurs already when roughly 40% of the battery’s capacity has been used — for example, when 40 Ah have been drawn from a 100 Ah battery. Because of this, AMF batteries are not suitable as house/auxiliary batteries where power is drawn over longer periods; they are best suited as starting batteries, where current is drawn for short bursts.

Charging an AMF battery takes a relatively long time — often between 8 and 16 hours for a full charge. Fast-charging it with too high a current can lead to overheating and the battery “boiling.” Therefore, chargers with a maximum current of 20 amperes are recommended. A charge cycle is defined as recharging the battery after it has dropped to around 20% of its capacity. An AMF battery usually manages 200–400 such cycles before performance begins to decline and replacement is needed. Also note that AMF batteries release a small amount of explosive hydrogen gas during charging. If the battery is installed in an enclosed space — for example, in a cab or cargo area — this gas must be vented out through a hose to avoid the risk of explosion or fire.

Advantages

• Affordable

Disadvantages

• Slow charging

• Short service life (200–400 charge cycles)

• Can only utilize about 40% of its capacity before recharging is required

• Emits explosive gas during charging

LEAD-ACID (EFB)

EFB (Enhanced Flooded Battery) is the type of flooded lead-acid battery that we stock at Work System. It is an improved variant of the traditional AMF battery, developed to provide better performance and a longer service life. EFB is therefore a better option than AMF.

Advantages (compared to AMF batteries)

• Charges faster than a standard AMF battery

• Can deliver up to 50% of its capacity before it needs recharging

• Manages approximately 300–600 charge cycles, which is about 50% more than a comparable AMF

General disadvantages

• Charges relatively slowly

• Can only utilize about 50% of its capacity before recharging is required

• Emits explosive gas during charging

LEAD-ACID (AGM)

We also stock AGM (Absorbent Glass Mat) batteries at Work System — an even more advanced type of lead-acid battery with several advantages over traditional counterparts. In an AGM battery, the electrolyte is absorbed in glass-fiber mats, which prevents acid stratification over time. This yields a more stable and efficient chemical reaction. As a result, you can use up to about 70% of the battery’s capacity before recharging, without damaging the battery.

AGM batteries can be charged almost twice as fast as traditional lead-acid batteries, without the risk of the battery starting to “boil.” The improved construction also contributes to a longer service life with up to 500–750 charge cycles. Since the electrolyte is bound in glass-fiber mats and not free-flowing, AGM batteries can be installed lying down or on their side, which is a major advantage in tight spaces. AGM batteries also do not emit gas under normal charging and therefore do not require a vent hose. For added safety, however, the battery is equipped with a pressure-relief valve that can release gas if the battery is damaged for any reason. Therefore, it’s still recommended to connect a vent hose as an extra safety measure.

Advantages (compared to EFB batteries)

• Approximately 20% higher usable capacity

• Nearly twice as fast charging compared to standard lead-acid batteries

• Can utilize about 70% of capacity before recharging

• Approximately 60% longer service life (500–750 charge cycles)

• Emits no explosive gas during charging

• Less sensitive to shock/vibration and does not have to be mounted upright

General disadvantages

• Higher price

• Sensitive to heat — should not be installed near heat sources such as the engine or a diesel heater without proper insulation/heat shielding

LITHIUM BATTERY

Lithium batteries represent a new generation of battery technology with significantly higher performance compared to traditional lead-acid batteries. One of the biggest advantages is that they can be fast-charged in roughly one hour, provided the charger is sufficiently powerful — about the same time it takes to discharge them. Unlike lead-acid batteries, you can utilize a full 100% of a lithium battery’s capacity, providing maximum energy yield. They also have a much longer service life, typically around 2,000–2,500 charge cycles. In addition, a lithium battery weighs about 60% less than comparable lead-acid batteries and can be installed lying down if space is limited.

Despite their advantages, lithium batteries have certain limitations. They are sensitive to cold and cannot accept charge at temperatures below 0 °C (32 °F). To address this, some models are equipped with an integrated heating element that preheats the battery before charging. Another option is to place the lithium battery on an external heating pad if internal heating is not available. Another important aspect is that all cells in the battery must have exactly the same voltage during operation. This is monitored and controlled by a built-in BMS (Battery Management System), which protects against overheating or, in the worst case, fire. The advanced technology makes lithium batteries considerably more expensive than traditional lead-acid batteries.

At Work System, we currently stock Clayton’s LPS system, where the lithium battery is integrated with an inverter, charger, and other electronics in a complete solution. We are also exploring the possibility of offering standalone lithium batteries in the future.

Advantages (compared to AGM batteries)

• Approximately 30% higher usable capacity

• Can utilize about 100% of capacity before recharging

• Can be charged extremely quickly

• Approximately 300% longer service life (2,000–2,500 charge cycles)

• Emits no explosive gas during charging

• Very low weight

General disadvantages

• High price

• Sensitive to low temperatures without auxiliary heating

Accessories

We also want to highlight our battery box (item no. 928-BATLÅDA), which comes complete with box, brackets, and tie-down strap. It’s a key component for installing an auxiliary battery in the vehicle in a simple, safe, and protected way. Since batteries are supplied without mounting hardware, the battery box is a practical and necessary accessory for a proper installation.

The Vehicle’s Electrical System

12V charging system (internal-combustion vehicles)

The classic electrical system in internal-combustion vehicles (diesel/gasoline) is designed so that an alternator monitors the starter battery’s charge level and charges it when needed. When an auxiliary battery was required to power additional equipment, a battery isolator relay was traditionally connected between the starter battery and the auxiliary battery. The relay’s function was to connect the starter battery and the auxiliary battery when the alternator was charging — which always occurred when the engine was running. When the vehicle was turned off and the auxiliary battery was used to power, for example, an inverter and the voltage quickly dropped, the isolator relay sensed this and disconnected the starter battery from the auxiliary battery to prevent the starter battery from being drained, which could otherwise prevent the vehicle from starting. When the vehicle was then started again and driven for at least half an hour, the alternator could usually regenerate the energy that had been consumed.

12V charging system (electric vehicles)

In electric vehicles, charging of the vehicle’s 12V battery works a bit differently. The 12V starter battery is usually smaller than in internal-combustion vehicles, which makes the need for an auxiliary battery even greater. Since EVs lack a traditional alternator, charging is handled by a DC/DC converter that draws power from the vehicle’s high-voltage traction battery and converts it to 12V. This converter rarely supplies more than about 20 amperes, so it’s important to harvest as much extra power as possible. This makes it particularly important to equip EVs with a DC/DC charger.

EURO 6 and smart alternators

When the Euro 6 emissions standard was introduced in 2014, it required all new internal-combustion vehicles in the EU to reduce exhaust emissions, achieved in part through increased fuel efficiency. This also affected the vehicle’s alternator, which is now software-controlled to charge the starter battery more sparingly to reduce engine load and thereby save fuel. In addition, the alternator is programmed never to fully charge the starter battery. This leaves room in the battery to store regenerated energy from engine braking, where kinetic energy is converted to 12V DC and used to charge the battery.

In short: a “smart alternator” means the vehicle does not store electrical energy the way you might expect — which is why alternative charging solutions are required to charge auxiliary batteries in modern vehicles.

CHARGING SOLUTIONS

Regardless of your batteries’ size or type, they need to be fully charged before the next use. Just like with a mobile phone, you can’t charge for only 10 minutes and expect the battery to last all day. Charging can occur while driving, which charges the batteries with a certain amount of current (amperes), but:

• Battery chargers are by far the best way to ensure the battery is fully charged at the start of the day

• Solar panels work well as a support/maintenance charger, but fully charging takes a long time (days).

Also keep in mind that…

• Battery age and health can affect runtime

• The maximum voltage allowed by the vehicle manufacturer from the alternator can affect charging and runtime

Recommended solution for maximum reliability

1. DC/DC charger: This is the foundation of all modern installations and ensures correct and full charging even in vehicles equipped with smart alternators (EURO 6+)

2. Shore power charger: Used when the vehicle is parked — for example, overnight — to fully charge the battery. Can also serve as a backup in high-consumption scenarios.

3. Solar panels: A perfect complement to the other systems; they keep the battery in good condition through maintenance or top-off charging.

4, Isolator relay (insufficient): Can be used in older vehicles, but provides no guarantees of a fully charged battery in modern installations.

Isolator relay

A battery isolator relay (also called a split-charge relay) is an electrical component that automatically connects or separates two batteries — usually the starter battery and an auxiliary battery — depending on voltage levels. Note! This solution often performs poorly in modern vehicles with smart alternators and control systems and is therefore not recommended by us.

How it works

When the engine is running and the alternator is charging, the starter and auxiliary batteries are automatically connected so both charge at the same time. When the engine is turned off, the connection is broken so the auxiliary battery cannot discharge the starter battery. This process is typically controlled by battery voltage — for example, the relay closes at about 13.3 volts and opens again when the voltage drops to around 12.8 volts.

Advantages

• Protects the starter battery

• Automatic operation

• Cost-effective solution

• Simple installation

Disadvantages

Disadvantages

• Simple logic — no smart charging

• Limited function in modern vehicles

• Not suitable for high power consumption or where fast charging is required

When is an isolator relay appropriate?

• In simpler installations with two batteries

• For users who want basic protection against unnecessary starter-battery discharge

• When the budget is limited and a DC/DC charger is not required

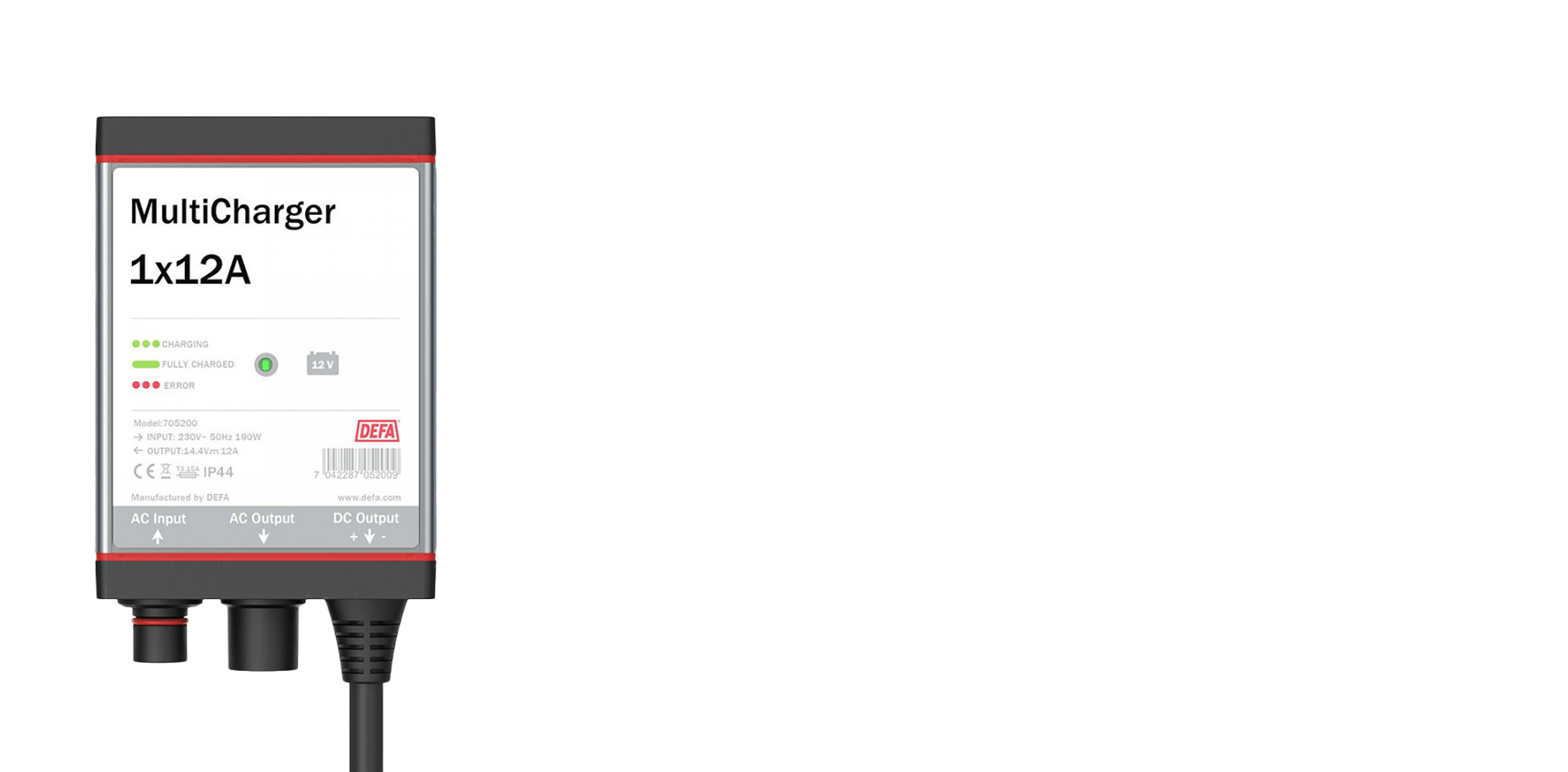

Shore power charger

A shore power charger — or a shore-power system — allows the vehicle to be connected to an external power grid. It is used to charge batteries, power electrical equipment, and supply vehicle equipment with electricity without the engine running. This is especially useful for work vehicles that stand still for extended periods or where something in the vehicle needs to operate overnight — for example, chargers for battery-powered tools.

How it works

The vehicle is connected via an inlet panel to a standard 230V outlet, and the power is then routed to an onboard battery charger that converts 230V AC to 12V DC.

Advantages

• Charges batteries while the vehicle is stationary

• Powers equipment without the vehicle running

• Saves fuel and reduces emissions

• Increases safety

• Maintains heating/cooling in, for example, the cargo compartment

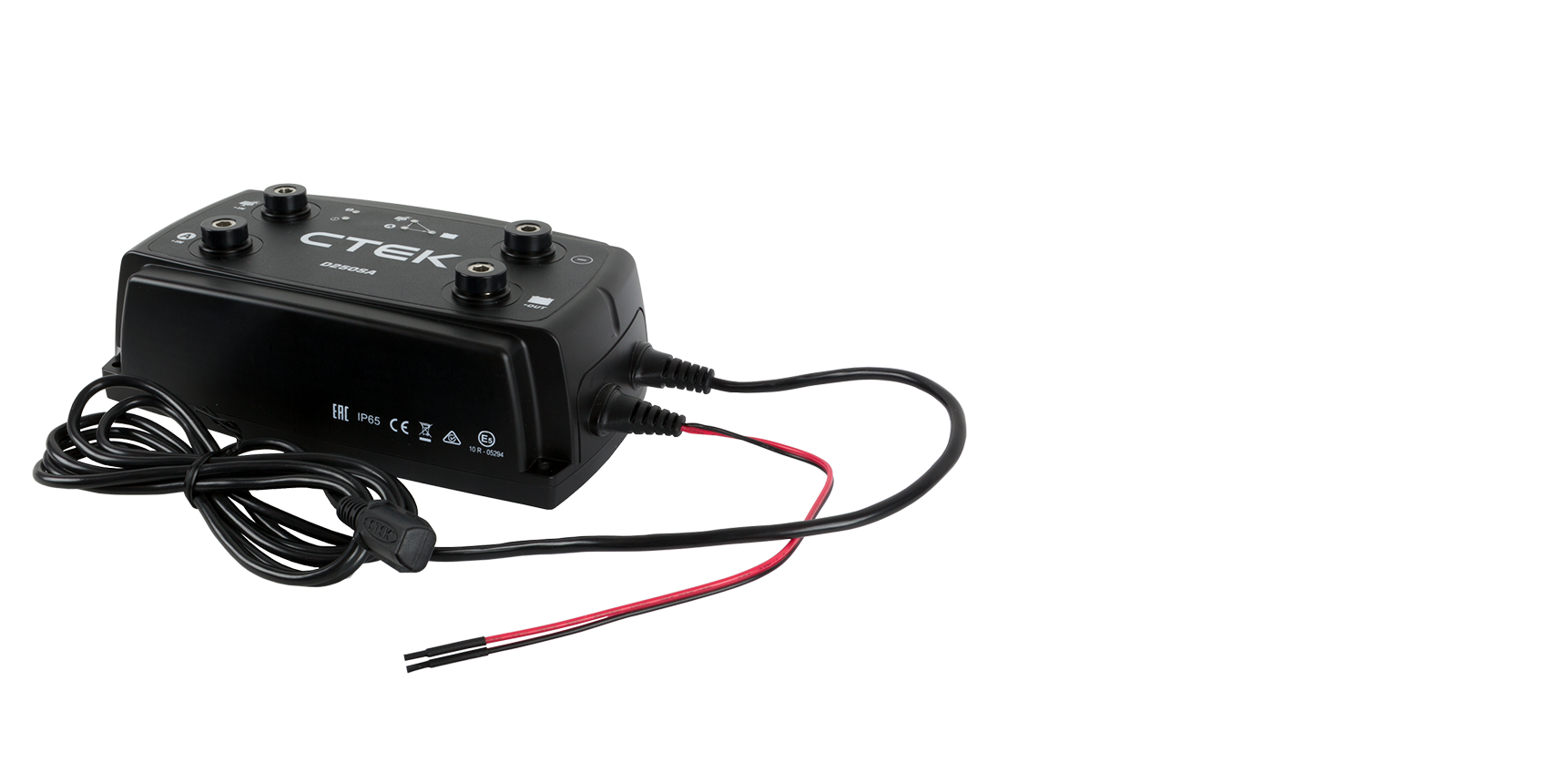

DC/DC CHARGER

A DC/DC charger — also called an alternator-fed battery charger — is used to charge an auxiliary battery via the vehicle’s electrical system in a controlled and efficient way. It is compatible with both vehicles that have traditional alternators and modern vehicles equipped with intelligent charging systems, such as Euro 6 engines and start/stop technology.

How it works

A DC/DC charger is installed between the starter battery and the auxiliary battery and activates automatically when the vehicle is in operation. It optimizes charging based on factors such as battery type, temperature, and current voltage.

Advantages

• Stable and efficient charging

• Compatible with modern vehicles (Euro 6 and up)

• Extends battery service life

• Safe and controlled operation

Disadvantages

• More expensive than an isolator relay

• More complex installation

• Requires correct sizing (20A, 30A, 50A)

When is a DC/DC charger most appropriate?

• In modern vehicles with smart alternators/start-stop function

• For high power consumption (tools, refrigerator, inverter, or similar)

• When using AGM, GEL, or lithium batteries

• When you want to maximize battery service life

COMPARISON: ISOLATOR RELAY VS. DC/DC CHARGER

| Features | Isolator relay | DC/DC charger |

|---|---|---|

| Price | Low | Higher |

| Charging quality | Basic | Optimized and safe |

| Compatible with Euro 6 | No | Yes |

| Installation | Simple | More advanced |

| Discharge protection | Yes | Yes |

| Battery types | Standard only | All (AGM, Lithium, etc.) |

Solar charging

Solar charging means that an auxiliary/house battery is charged via solar panels that capture sunlight and convert it into electricity. The panels are often mounted on the roof and connected to a charge controller (MPPT or PWM).

How it works

The solar panel converts sunlight into 12- or 24-volt DC, which is then routed to a controller. The controller’s task is to manage and optimize charging to the auxiliary battery so it occurs safely and efficiently. Charging is slow and continuous as long as there is sufficient light, and it works best in clear, sunny conditions.

Advantages

• Free and renewable energy

• Perfect for maintenance charging

• Handles lighting, cooler, alarm, tool chargers, or similar

Disadvantages

• Not designed for fast charging (depending on the number of panels, at best 2–10 A)

• Highly weather-dependent (clouds, shade, winter = low output)

Less suitable applications for solar

• Fast charging of depleted batteries

• High current consumption (inverter, power tools)

• Handles lighting, cooler, alarm, tool chargers, or similar

• Primary charging source under demanding conditions